KAMAL

MyBoerse.bz Pro Member

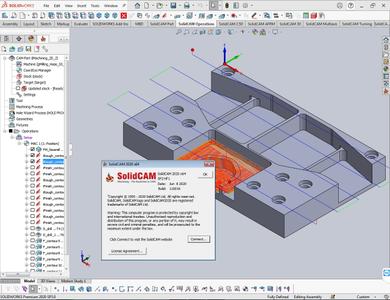

SolidCAM 2020 SP1 HF1 x64 Multilingual

SolidCAM 2020 SP1 HF1 x64 Multilingual | 4.6 GB

Languages: 中文, Čeština, Dansk, Nederlands, English, Français, Deutsch, עברית, Magyar, Italiano, 日本語, 한국어, Polski, Português, Русский, Español, Türkçe.

SolidCAM has launched Hot Fix 1 for their flagship CAM software - SolidCAM 2020 SP1. Last release brings major enhancements to many CAM modules available inside SolidCAM, as well as general improvements that provide an even greater ease-of-use for the end user.

SolidCAM 2020 SP1 HF1 Release Notes - Date: May 10, 2020

SOL-11463 simulation / Shows falls rotary axis movement in simulation data

SOL-11647 MCO / Main Spindle movement without part not possible

SOL-12083 Language/Italian/UI problems

SOL-12208 Convert part from SC 2019/ unable to calculate operation

SOL-12237 Multiaxis / Machine control / UI Error

SOL-12239 GUI\all types of part-open part setting -cancel or save-computer is stuck if template drag-drop is missing

SOL-12261 Gcode/Coolant/minimum_quantity_L error

SOL-12262 Overlapping of GUI elements

SOL-12273 Turning - synchronization issue

SOL-12278 simultaneous turning\3D view tool orientation and Visual tool (near mouse) in the job are incorrect

SOL-12283 SolidVerify/Missing check box

SOL-12305 G-code / output is not correct

SOL-12308 2D chain geometries / not possible anymore to trim/extend

SOL-12318 Simultaneous Turning\geometry\the start of geometry in simultaneous turning is wrong until you save Modify geometry

SOL-12340 Gcode/Custom plane/wrong start,end_angles

SOL-12345 GUI / GUI Improvement Requests in Drag & Drop Task pane

SOL-12346 Tool Definitions in Inch are incorrect

SOL-12385 Pocket Recognition/Remove 3D Gauge Protection inSP1

SOL-12391 Drag & drop doesn't support Czech characters

SOL-12453 Chamfer recognition/direction/Climb should be on left side

SOL-12461 Hole Wizard/bad upper level with far countersink

SOL-12471 4x transform/Wrong second axis angle in @start_of_job

SOL-12481 Inch/Metric STL Tool Holder Fails

SOL-12586 5x/Crash on calculate

SolidCAM is a CAM software that integrates directly into SolidWorks and Inventor. That does not only mean you can program tooling paths from the comfort of the CAD software you know and love, but it is also advantageous in that all tool paths retain associativity with the original CAD design. In other words, any changes made to the CAD file will instantly be reflected in updated tool paths, saving you time and money.

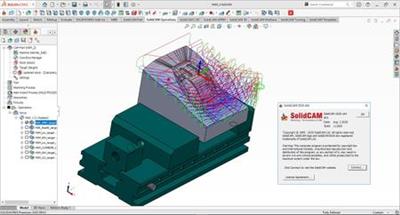

Take out the guesswork of milling, turning and other processes by using the patented Technology Wizard. The wizard allows you to automatically fine-tune optimized feeds, speeds, depth and width of cuts. What is more, this CAM software automatically recognizes the distinct geometrical features of your design and assigns toolpaths accordingly. Hence, this approach eliminates the need for time-consuming manual geometry definition.

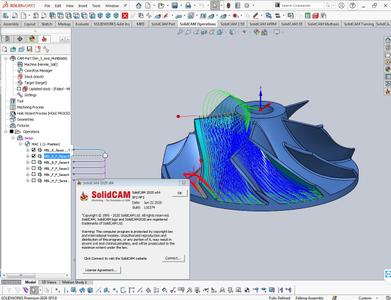

The tool paths created with this CAM software rely on an advanced, patented morphing spiral that gradually conforms to the geometry of the feature being machined rather than an old-fashioned, simple spiral tool path. This increases the amount of time the tool actually works the stock and thus makes your machine more productive.

SolidCAM & iMachining - The amazing CAM solution.

SolidCAM Inc is a world leader in advanced tool path generation technology (CAM) running directly inside SolidWorks. SolidCAM features a full line of CNC machine programming software solutions ranging from 2 axis lathes and 3 axis mills to extremely complex multi-axis MillTurn machines and Wire Edm. All products run directly inside SolidWorks and provide the user with a true "SolidWorks look and feel" for ease of use and maximum efficiency. Along with the integrated interface and scalability for new machines, SolidCAM also has its patented "iMachining" that powers users to new levels of productivity and profits, through unmatched cycle time reduction and unrivaled tool life.

Product: SolidCAM

Version: 2020 SP1 HF1 build 109208

Supported Architectures: x64

Website Home Page :

Language: multilanguage

System Requirements: PC *

Supported Operating Systems: *

Software Prerequisites: SolidWorks 2012-2020

Size: 4.6 Gb

Microsoft Windows 10 x64 Professional and Enterprise Editions; Microsoft Windows 8.1 x64 Professional and Enterprise Editions (with latest Service Pack); Microsoft Windows 7 x64 Professional and Ultimate Editions (with latest Service Pack)

- Intel Xeon, Intel Core, Intel Core 2 Duo, Intel Core 2 Quad or higher (If you use other processors we assume no responsibility and no support)

- 4 GB RAM (for the processing of large components, we recommend 8 GB RAM (or more)

- 15 GB free disk space for installation

- Hard disk with at least 100 GB of storage

- NVIDIA graphics card of the current Quadro series with min. 512 MB (1024 MB recommended) and current, certified graphics driver (With the use of other and on-board graphics cards, we accept no responsibility and no support)

- 1,280 x 1,024 or higher screen resolution

- Microsoft Direct3D 9 or compatible graphics card (Microsoft Direct3D 11 or higher recommended)

- USB 2.0 interface

- DVD drive

DOWNLOAD LINKS:

SolidCAM 2020 SP1 HF1 x64 Multilingual | 4.6 GB

Languages: 中文, Čeština, Dansk, Nederlands, English, Français, Deutsch, עברית, Magyar, Italiano, 日本語, 한국어, Polski, Português, Русский, Español, Türkçe.

SolidCAM has launched Hot Fix 1 for their flagship CAM software - SolidCAM 2020 SP1. Last release brings major enhancements to many CAM modules available inside SolidCAM, as well as general improvements that provide an even greater ease-of-use for the end user.

SolidCAM 2020 SP1 HF1 Release Notes - Date: May 10, 2020

SOL-11463 simulation / Shows falls rotary axis movement in simulation data

SOL-11647 MCO / Main Spindle movement without part not possible

SOL-12083 Language/Italian/UI problems

SOL-12208 Convert part from SC 2019/ unable to calculate operation

SOL-12237 Multiaxis / Machine control / UI Error

SOL-12239 GUI\all types of part-open part setting -cancel or save-computer is stuck if template drag-drop is missing

SOL-12261 Gcode/Coolant/minimum_quantity_L error

SOL-12262 Overlapping of GUI elements

SOL-12273 Turning - synchronization issue

SOL-12278 simultaneous turning\3D view tool orientation and Visual tool (near mouse) in the job are incorrect

SOL-12283 SolidVerify/Missing check box

SOL-12305 G-code / output is not correct

SOL-12308 2D chain geometries / not possible anymore to trim/extend

SOL-12318 Simultaneous Turning\geometry\the start of geometry in simultaneous turning is wrong until you save Modify geometry

SOL-12340 Gcode/Custom plane/wrong start,end_angles

SOL-12345 GUI / GUI Improvement Requests in Drag & Drop Task pane

SOL-12346 Tool Definitions in Inch are incorrect

SOL-12385 Pocket Recognition/Remove 3D Gauge Protection inSP1

SOL-12391 Drag & drop doesn't support Czech characters

SOL-12453 Chamfer recognition/direction/Climb should be on left side

SOL-12461 Hole Wizard/bad upper level with far countersink

SOL-12471 4x transform/Wrong second axis angle in @start_of_job

SOL-12481 Inch/Metric STL Tool Holder Fails

SOL-12586 5x/Crash on calculate

SolidCAM is a CAM software that integrates directly into SolidWorks and Inventor. That does not only mean you can program tooling paths from the comfort of the CAD software you know and love, but it is also advantageous in that all tool paths retain associativity with the original CAD design. In other words, any changes made to the CAD file will instantly be reflected in updated tool paths, saving you time and money.

Take out the guesswork of milling, turning and other processes by using the patented Technology Wizard. The wizard allows you to automatically fine-tune optimized feeds, speeds, depth and width of cuts. What is more, this CAM software automatically recognizes the distinct geometrical features of your design and assigns toolpaths accordingly. Hence, this approach eliminates the need for time-consuming manual geometry definition.

The tool paths created with this CAM software rely on an advanced, patented morphing spiral that gradually conforms to the geometry of the feature being machined rather than an old-fashioned, simple spiral tool path. This increases the amount of time the tool actually works the stock and thus makes your machine more productive.

SolidCAM & iMachining - The amazing CAM solution.

SolidCAM Inc is a world leader in advanced tool path generation technology (CAM) running directly inside SolidWorks. SolidCAM features a full line of CNC machine programming software solutions ranging from 2 axis lathes and 3 axis mills to extremely complex multi-axis MillTurn machines and Wire Edm. All products run directly inside SolidWorks and provide the user with a true "SolidWorks look and feel" for ease of use and maximum efficiency. Along with the integrated interface and scalability for new machines, SolidCAM also has its patented "iMachining" that powers users to new levels of productivity and profits, through unmatched cycle time reduction and unrivaled tool life.

Product: SolidCAM

Version: 2020 SP1 HF1 build 109208

Supported Architectures: x64

Website Home Page :

Code:

Language: multilanguage

System Requirements: PC *

Supported Operating Systems: *

Software Prerequisites: SolidWorks 2012-2020

Size: 4.6 Gb

Microsoft Windows 10 x64 Professional and Enterprise Editions; Microsoft Windows 8.1 x64 Professional and Enterprise Editions (with latest Service Pack); Microsoft Windows 7 x64 Professional and Ultimate Editions (with latest Service Pack)

- Intel Xeon, Intel Core, Intel Core 2 Duo, Intel Core 2 Quad or higher (If you use other processors we assume no responsibility and no support)

- 4 GB RAM (for the processing of large components, we recommend 8 GB RAM (or more)

- 15 GB free disk space for installation

- Hard disk with at least 100 GB of storage

- NVIDIA graphics card of the current Quadro series with min. 512 MB (1024 MB recommended) and current, certified graphics driver (With the use of other and on-board graphics cards, we accept no responsibility and no support)

- 1,280 x 1,024 or higher screen resolution

- Microsoft Direct3D 9 or compatible graphics card (Microsoft Direct3D 11 or higher recommended)

- USB 2.0 interface

- DVD drive

DOWNLOAD LINKS:

Code:

Code:

Code:

Code: